$150.00 Original price was: $150.00.$99.99Current price is: $99.99.

- Reliable Payments for Reliable Shopping

- Experience the Best Quality

- Multiple payment methods, 100% payment security

- Your Security is Our Promise

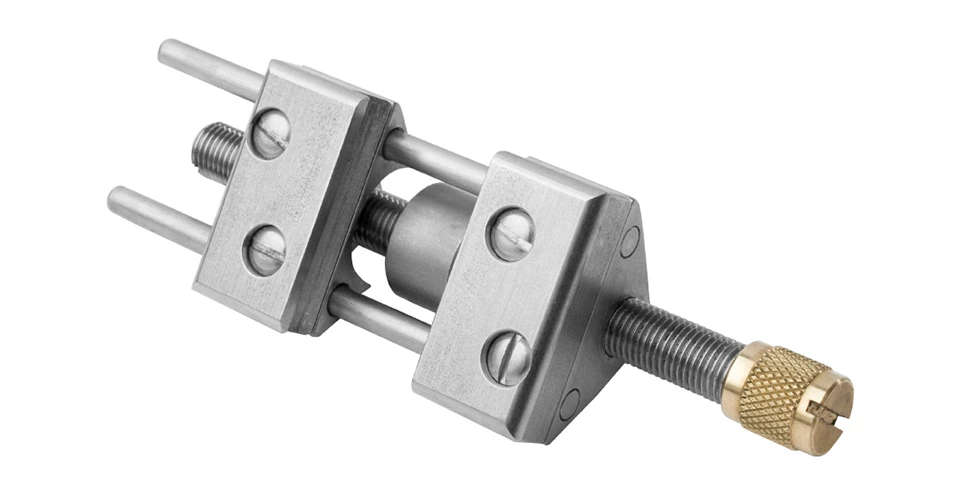

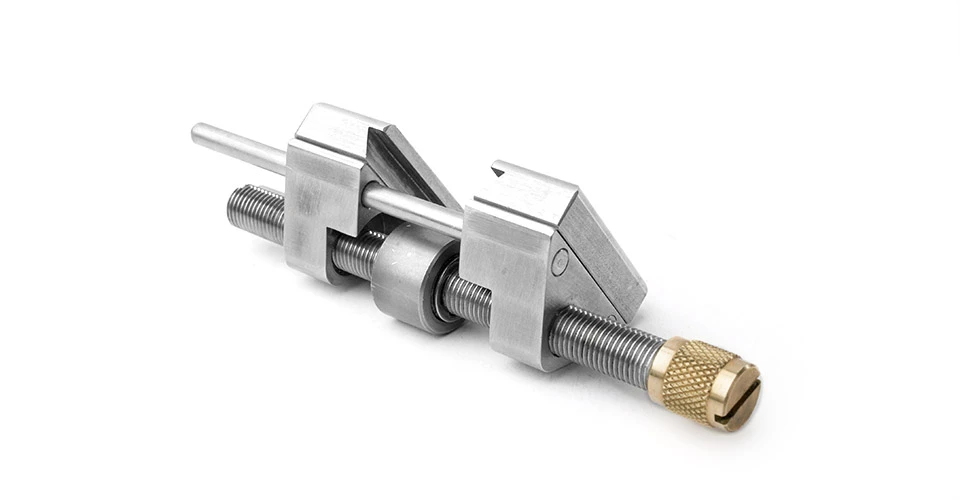

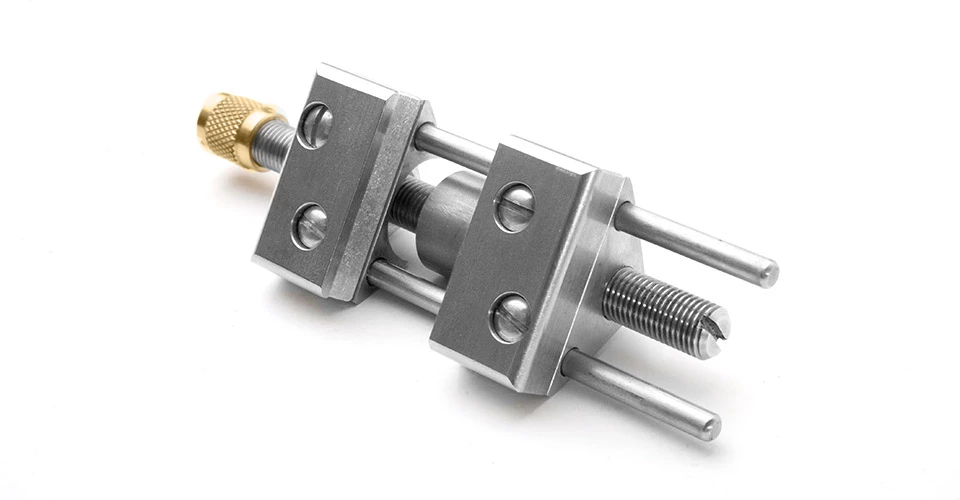

Lie-Nielsen Honing Guide

Our version of the side clamping style of honing guide is solidly machined from Stainless Steel, with a Bronze bearing.

The Honing Guide features removable jaws: it comes with a standard pair of jaws that fit most of our blades, and additional jaws are available (sold separately) for Chisels 1/4″ and under, tall jaws for Mortise Chisels, long jaws for very short blades and angled jaws for Skew Blades. We have designed these jaws for our blades and chisels, not other makers’.

For information on angle setting, click on the “Use” tab above.

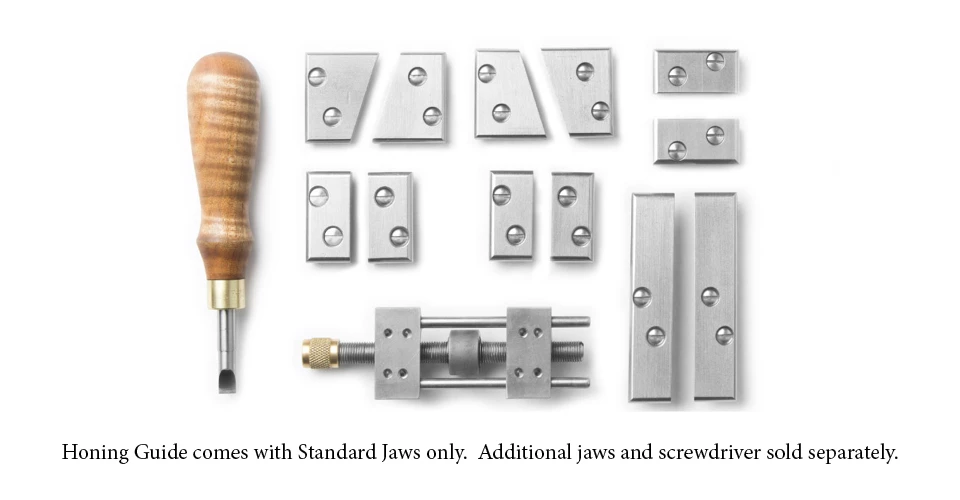

Lie-Nielsen Honing Guide Jaws

- The Standard Jaws (included with the Honing Guide) fit most of our plane blades, as well as our 5/16″ to 1″ Bevel Edge Chisels.

- The Chisel Jaws fit our 1/8″, 3/16″, and 1/4″ Bevel Edge Chisels (as well as our other Bevel Edge Chisels up to 3/4″).

- The Mortise Chisel Jaws fit all of our Mortise Chisels except the 1/10″, and also accommodate our larger Bevel Edge Chisels.

- The Long Jaws fit blades for all of our Spokeshaves and for the following Lie-Nielsen planes: No. 610, 10-1/4, 041, 042, 073, 101, 100, and 1/2. These jaws are reversible. The short end hones a bevel up to 40° and the long end hones a bevel up to 30°.

- The 18° Skewed Jaws fit our No. 140 Skew Block Plane (left or right hand). The blade for the left hand No. 140 fits with the left skewed jaws, and the blade for the right hand No. 140 fits with the right skewed jaws.

- The 30° Skewed Jaws fit our No. 98/99 Side Rabbet Planes (left or right hand). The blade for the No. 98 fits with the right skewed jaws, and the blade for the No. 99 fits with the left skewed jaws.

For more information about sharpening, download our Sharpening Instructions PDF and Deneb Puchalski’s Angle Setting Jig PDF.

Patented.

Honing a New Blade

About the Lie-Nielsen Honing Guide

Materials:

All parts are Stainless Steel, Brass, or Bronze. Keep the threads free of grit by rinsing off with water after use, but wipe off excess. If you want to oil the threads, use a light machine oil. This is not necessary.

Maintenance:

All parts are replaceable and available from us. To disassemble, use two screwdrivers to remove the Brass nut. The Brass nut is reverse-threaded and is secured with reversible (green or blue) Locktite. Unthread

the threaded rod from the body, remove one retaining clip to remove the roller bushing assembly. Reassemble in reverse order.

Guarantee:

Materials and workmanship are guaranteed for the life of your tool. Call for repairs or replacement parts. We are available for advice if you ever have a problem using your tool.

Proposition 65 Notice: Bronze and brass alloys contain lead, a chemical known to the State of California to cause cancer and birth defects, or other reproductive harm. Wash hands after handling.

Reviews

There are no reviews yet.